Project Update Bulletin 20

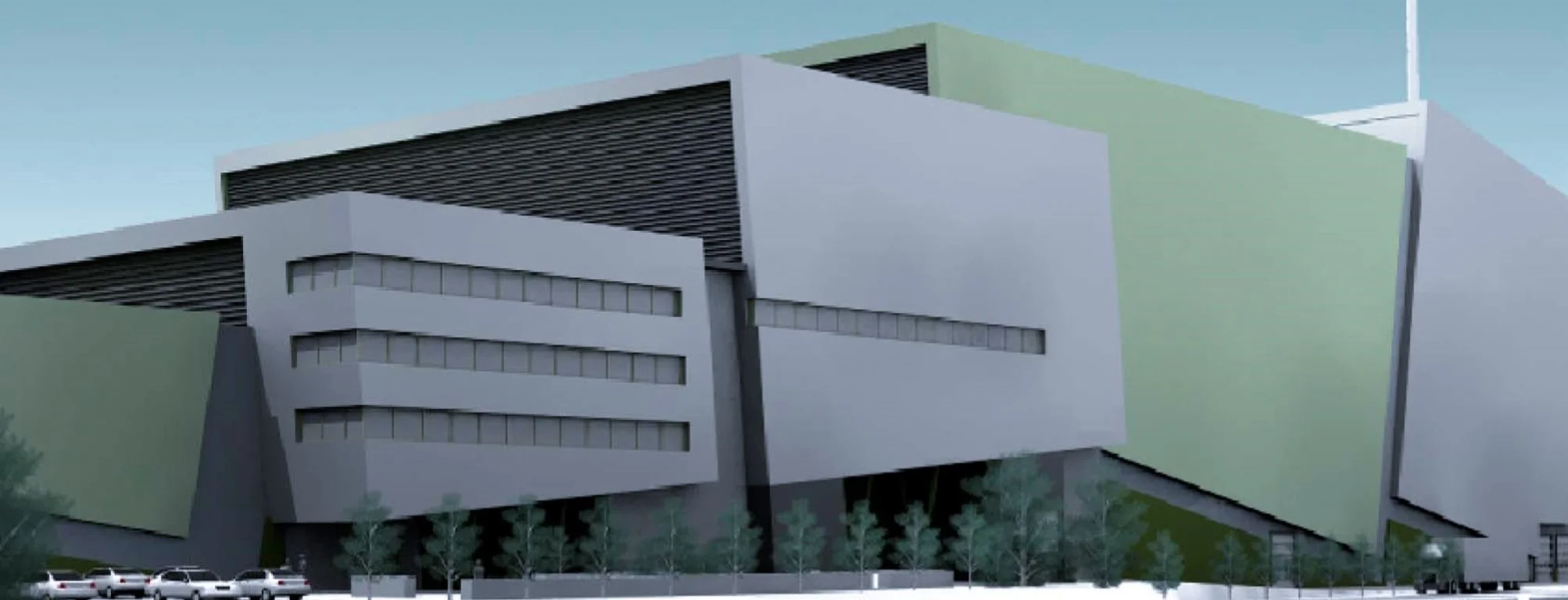

/Construction of the facility is almost complete with most of the physical elements having been installed. The final parts of the building’s facade are being fitted ready for installation of the external louvres, which control air movement coming in and out, due to start in February.

Read More