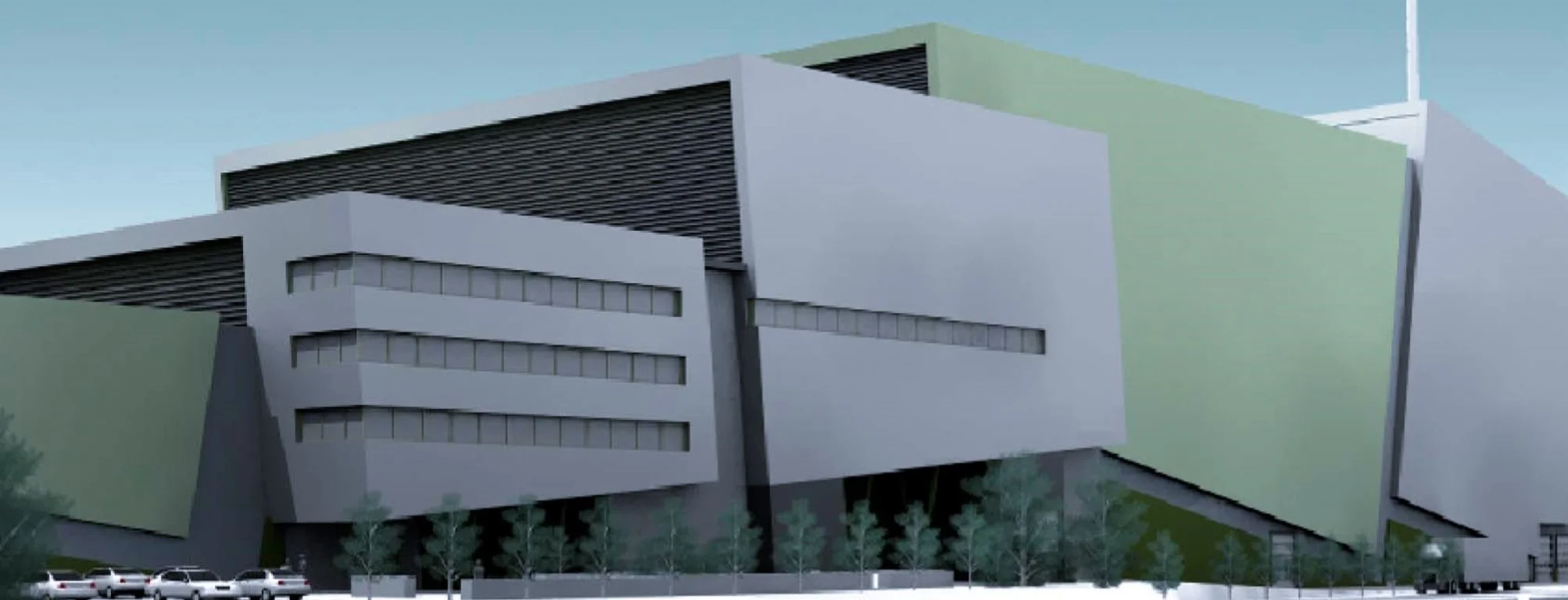

Gloucestershire Energy from Waste facility connected to the National Grid

/● The facility now has electricity via the 33kVa cable installed by Western Power Distribution

● The cable will initially provide power to the site for commissioning trials and then allow electricity to be exported back to the National Grid once the facility is fully operational

● The energisation of the facility is a key construction milestone

Urbaser Balfour Beatty (UBB) has successfully energised the Gloucestershire Energy from Waste facility by connecting the facility to the National Grid and powering the site for initial commissioning trials.

The 33kVa cable connecting the facility to the grid has been fully installed and tested, enabling work to begin on the cold commissioning of the facility later this year. Tests during cold commissioning ensure that all the equipment is set up and functioning correctly. It is a standard part of the construction process for Energy from Waste facilities, and does not involve the burning of waste. Once the facility is operational, the dual-purpose cable will also export electricity generated at the facility back to the National Grid.

Commenting on the milestone, Andrew Bendall, UBB’s Project Director for the construction phase said:

“We are delighted to have reached this very important milestone in the construction plan. This now allows us to proceed through the next stages of cold commissioning and then to hot commissioning trials so that the facility is ready to operate next summer.”

October also saw other project milestones successfully achieved. The insulation of the ash hoppers to collect incinerator bottom ash was completed, and the water main was also installed on site and will soon be connected to the main water supply, which will provide water to the facility. The water main within the boiler is currently being insulated so as to protect the boiler from damage during the high temperatures experienced when converting waste into energy, and externally to reduce any heat loss during this process and improve the overall efficiencies of the process.

For more information, please visit www.ubbgloucestershire.co.uk